Engineering

Services

Elinor Coatings provides technical consulting services in coatings and surface failure analysis, design, development, and testing to business and government clients. If you need to protect your product or process from corrosion with efficient solutions, you can trust us to protect your success and propel your business forward.

FEDERAL CONTRACTING

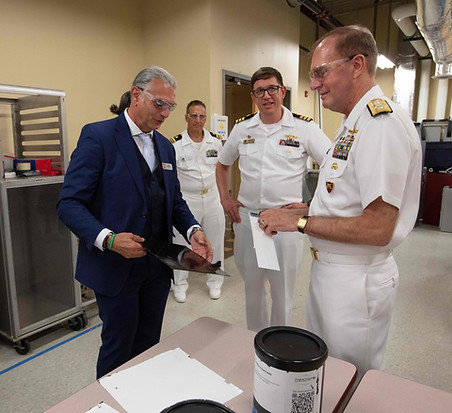

From corrosion-resistant coatings for military equipment and vehicles to specialized coatings for aerospace components, our solutions are designed to withstand the harshest environments and ensure the reliability and longevity of vital defense systems. We are committed to delivering coatings that not only meet the stringent requirements of the DoD but also exceed expectations in terms of quality, efficiency, and environmental sustainability.

-

DCAA Approved Accounting

-

CMMC Cybersecurity 2.0

-

PMP Certified Employees

NAICS:

541712: Research & Development in Physical, Engineering & Life Sciences

541713: Research & Development in Nanotechnology

541690: Other Scientific & Technical Consulting

325510: Paint & Coating Manufacturing

PAST PERFORMANCES

DoD US Air Force Research Laboratory

Corrosion/Coatings Development

DoD US Army Research Laboratory

Corrosion/Intelligent Coatings Development

DoD US Navy - NSRP

Coatings Development

OUR APPROACH TO CORROSION ENGINEERING

Elinor Coatings provides comprehensive corrosion engineering services for aerospace, maritime, and ground vehicles, specializing in corrosion consulting, product development, and material testing. When a failure occurs, our expert team steps in to thoroughly analyze the problem, identify the root cause, and formulate a targeted solution. This may involve developing a brand-new coating specifically designed for your needs or recommending and applying one of our existing, chromate-free, high-performance coatings. We then rigorously test the proposed solution to ensure it effectively mitigates the corrosion issue and delivers lasting protection.

COATING DEVELOPMENT AND OPTIMIZATION

Elinor Coatings solves surface challenges by optimizing existing formulations and developing innovative materials for new regulations or discontinued products. We provide expert, tailored solutions for your specific needs, including small-batch manufacturing for our specialty coatings.

Elinor Coatings delivers exceptional outcomes, enhancing existing coatings or identifying novel alternatives for performance, durability, and compliance. We commit to finding effective, compliant, lightweight, and environmentally sound chromate-free, isocyanate-free, and HAPS-free formulations, diligently working to meet your specifications.

CONSULTING

Facing galvanic corrosion or surface protection challenges in your operations? Elinor Coatings, based in Fargo, North Dakota, offers expert consultation to quickly identify issues and provide cost-effective solutions. Our team includes staff certified to AMPP CIP Level 1 and CP Level 4, and our CTO, Dante Battocchi, brings over 20 years of experience in corrosion and coatings studies. Request a tailored quote today and let our expertise save you valuable time and resources.

Our consultation process focuses on gathering essential information to accurately assess corrosion factors and develop targeted solutions. You will receive thorough and detailed insights to guide your next steps. Initial consultation is based on an hourly rate, including travel, with follow-up services available.

OUR PROCESS

01

On-Site Investigation

An Elinor Coatings consultant will conduct a one-day on-site visit to your facility—be it a manufacturing plant, shop, shipyard, or other location—to meticulously collect the data needed for a thorough understanding of your corrosion issues.

02

In-Depth Analysis

Our team conducts a comprehensive analysis of the gathered information to determine the precise causes of the corrosion problem. We then develop a report outlining viable solutions.

03

Clear and Actionable Reporting

You will receive a detailed report from Elinor Coatings outlining the identified issues, along with various options and clear recommendations for effective mitigation and resolution.